1971 Upper Clyde Shipbuilders 2000 HP Jack Up

1971 Upper Clyde Shipbuilders 2000 HP Jack Up

Contact us for price

Location:Turkey

Available quantity:1

Description

MOBILE JACK-UP CANTILEVER DRILLING RIG, SELF PROPELLED.

SELF ELEVATING, 4 LEGS DESIGN

CONSTRUCTION YARD: JOHN BROWN, CLYDE, SCOTLAND

YEAR OF CONSTRUCTION: 1971

REFURBISHED AND UPGRADED: 2015

LAST CAT IV: 2015

LAST UT. WALL THICKNESS GAUGE REPORT: 2016

Last class survey was conducted in August 2015. Major Renovation was made in 2015, with small part-time jobs and preventive maintenance being done within the subsequent years. Last condition assessment was conducted in December 2017.

LAST INSPECTION: December, 2017

ANY AND ALL DOCUMENTATION WILL BE MADE AVAILABLE TO QUALIFIED BUYER AFTER RECEIPT OF DEPOSIT.

See DOCUMENTS section for complete specification sheet.

MAIN DIMENSIONS

OVERALL LENGTH (INCLUDING HELIDECK): 286 ft

OVERAL WIDTH (INCLUDING ANCHOR RACKS): 141 ft

HULL LENGTH: 297 ft

HULL WIDTH: 141 ft

HULL DEPTH: 22 ft

NUMBER OF LEGS/LENGTH: 4x356 (INCLUDING SPUD CAN)

LEG LENGTH AVAILABLE BELOW HULL: 306 ft (INCLUDING SPUD CAN)

TYPE OF LEG: TRIANGULAR TRUSSED

LIGHT SHIP: 11,809 lt

DISPLACEMENT AT LOADLINE: 11,801 lt

STORAGE CAPACITIES

VARIABLE LOAD CAPACITY (EXCLUSIVE OF DRILLING LOADS): 2789 s tons

FUEL: 4,980 bbl.

DRILLING WATER: 3,442 bbl.

PORTABLE WATER: 700 bbl.

MUD PROCESSING TANK: 417 bbl.

ACTIVE LIQUID MUD: 1,904 bbl.

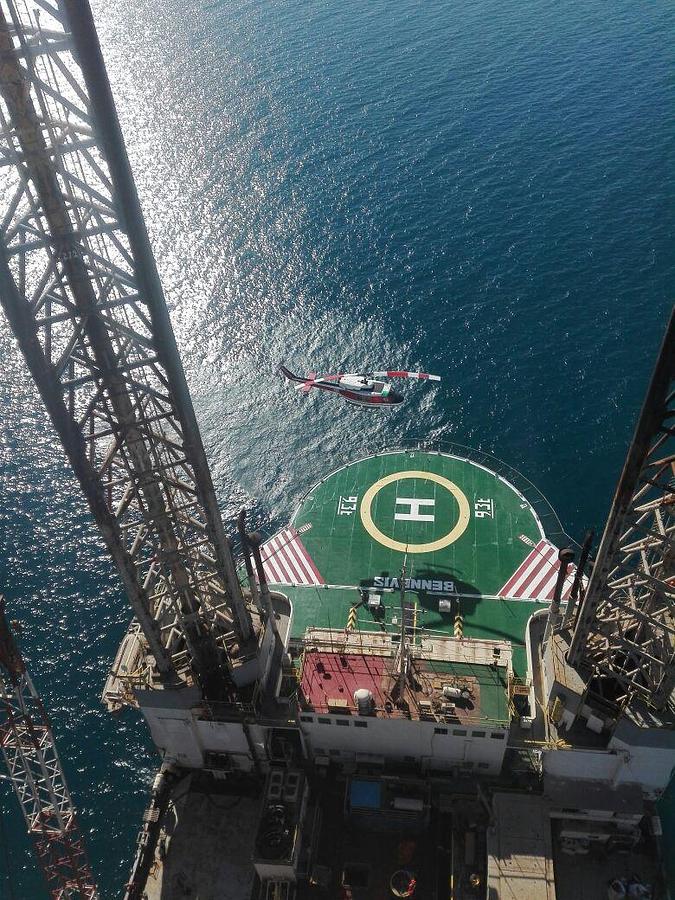

HELICOPTER LANDING DECK

LOCATION (FRWD/AFT/PORT/STBD): BOW

DIMENSIONS: 72.8 ft

PERIMETER SAFETY NET FITTED

DESIGNED FOR HELICOPTER TYPE: S61N – BELL 212 – DOLPHIN

COVERED BY FOAM FIRE SYSTEM: YES

DRILLING EQUIPMENT & LAYOUT

DERRICK: Lee C. Moore, 30 ft X45 ft base x 160 ft high. Rated at 1,300,000 lbs.

SET BACK CAPACITY: 175 stands of 5-inch drill pipe and 7 stands of g 1/2-inch collars.

DERRICK OUTFIT

DEADLINE ANCHOR – National Type E with Martin Decker E-80 Sensator. Lee C. Moore 3-well.

500T CROWN BLOCK equipped with 7 × 60-inch sheaves National 60-G500, 500 t combination hook and travelling block.

VARCO TOP-DRIVE. Model TDS-3, drilling system complete with 1000 hp DC drilling motor assembly reduction gears, torque wrench (pipe handler), support and drillers control consol.

Two National Model P-500 swivels.

DRAW- WORKS

National Model 1320 UE driven by two GE 752 DC motors of 1000 hp each. Draw-works complete with Baylor Model 7828 dynamic auxiliary brake.

Lebus grooving for 1 3/8-inch wireline.

National Type B-1 make-up and breakout catheads, and Crown-o-Matic crown block protector.

Halliburton wire line unit complete with 14000 ft of 0.092-inch wire.

TOTCO single shot non- directional survey instrument.

ROTARY

National Type C-375 (37-1/2 inch).

Rotary is complete with Varco 6600 Type MPCH master casing bushing and Varco type HDP roller Kelly bushing (Rotary is available as back – up to Top Drive system if required.

CANTILEVER AND SUB- STRUCTURE SKIDDING

Drilling area

10 ft to 60 ft outreach and 10ft either side of drill center.

The Cantilever includes a pipe rack. (There is another pipe rack on the main deck)

BLOW.OUT PREVENTION & WELL CONTROL

Blow-out Prevention

Two Double Cameron 13-5/8* Type U. 10,000 psi Working Pressure.

One Hydril 13-5/8*, Type GL spherical BOP- 5,000 psi WP annular type.

One Shaffer 20° annular BOP – 2000 psi WP.

CHOKE MANIFOLD

Cameron 3-1/16* – 10,000 Psi W

BOP CONTROL

Koomey Model T-151-60 (160 gals) with remote control Unit Model T .151-80-35

DIVERTER

Hydril 29-1/2*, Type MSP- 500 Psi WP.

MUD SYSTEM

Two National Type 12P-160 Mud Pumps, 5,000 PSI

Two Mission 6* x 8° centrifugal mud mixing Pumps.

Two Mission 6° x 8° centrifugal Pumps for de-sander and de-siller service.

Brandt Dual tandem Screen high speed shale shaker.

Three derrick FloLine Mud Cleaners.

One Demco Model 123 de-sander with three 12° Cones.

One Demco Model 416-h desilter with sixteen 12* Cones.

One MI SWACO mud cleaner with eight 4″ Cones.

One atmospheric-type de-gasser with vent line to top of derrick.

One MI-SWACO vacuum- type de-gasser.

MUD PROCESSING

One re-circulating trip tank – 25 bbls.

Four solids removal tanks – 98 bbls each.

Two active mud tanks and two reserve tanks – 400 bbls each.

One pill tank – 50 bbls.

Dual standpipes and standpipe manifold – (5000 psi WP. Two rotary hoses 3-1/2″ ID- 5000 psi WP. Six 1400 cu.ft. horizontal pneumatic-type bulk mud/cement storage tanks (three for mud).

Two low pressure bulk air compressors.

Cementing unit with re-circulating mixer.

POWER

GENERATORS

Four Alco Model 215-V-12 diesel-electric engines of 2,250 hp each.

Four GE GT 608 2,250 hp continuous input DC generators for propulsion and drilling.

Two Caterpillar 3516B diesel engine each driving 1825 KW AC generator.

One Caterpillar D399-TA diesel engine driving one 800 KW AC generator.

One Perkins 4236-56 hp diesel engine driving one 30 kW emergency generator.

See DOCUMENTS section for complete specification sheet.

Contact:

Jose Lozano

jlozano@vidabem.us

800 957 2391

Subject to prior sale and or other disposition.

Purchasing Party is responsible for verifying accuracy of information provided. All Items to be quoted in US currency. All prices and availability are subject to change without notice and are subject to applicable sales tax. Title to all goods listed remain with the seller until the purchase price is fully paid. Equipment is purchased as is, where is, without warranty unless otherwise specified. Use hours are estimate hours as of the date of this posting and are not guaranteed. Equipment pictured may contain attachments and/or accessories not priced in this offer. Sale subject to terms and conditions on final bill of sale.

Visit Us On LinkedIn

https://www.linkedin.com/company/vida-eq

Specifications

| Manufacturer | Upper Clyde Shipbuilders |

| Model | 2000 HP Jack Up |

| Year | 1971 |

| Condition | Used |

| Stock Number | 8917105444 |

| YEAR OF CONSTRUCTION | 1971 |

| CONSTRUCTION YARD | JOHN BROWN, CLYDE, SCOTLAND |